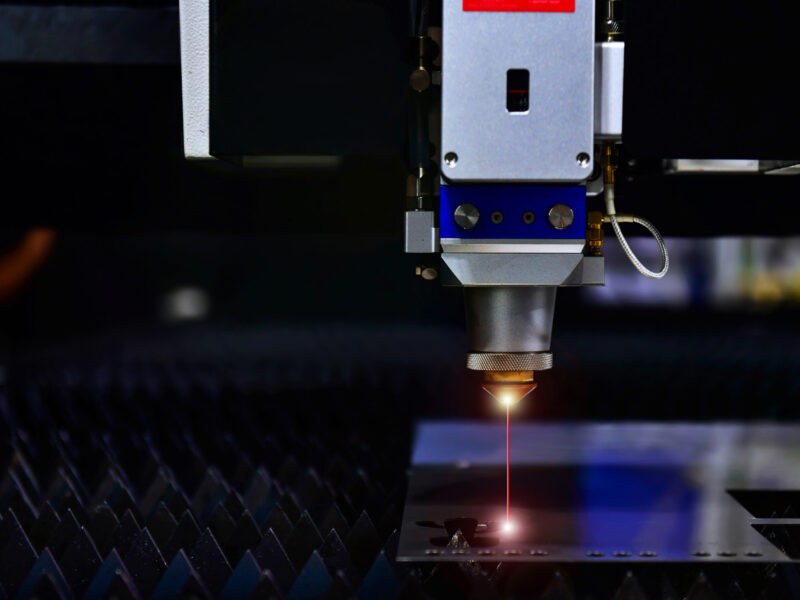

Nitrogen plays a key role in the laser cutting process. It helps in achieving a high-quality cut with clean edges. Common materials for which nitrogen is used include stainless steel, aluminum, and its alloys. Industrial nitrogen is ideal for the laser cutting process because of its inherent cleanliness and purity.

To assess which nitrogen gas generation system is best suited for the process, businesses should consider the following factors:

- Required purity level

- Size of the nitrogen generation unit, so that it caters to majority of nitrogen needs

- Nitrogen requirement

- Hours of laser cutting operation

- Nitrogen pressure

- Type of metal

- Type of laser

Nitrogen gas generators are a great option, especially for fiber lasers that typically require higher consumption. VedFirms nitrogen plant allows you to produce all the nitrogen you need when you need it. The cost of our nitrogen generation unit is much less compared to nitrogen cylinders. Our nitrogen gas is produced at 99% to 99.999% purity.

Investing in an N2 generation plant is the best way to cut laser operating costs and improve operational efficiency. If you are interested in having your own onsite nitrogen generator, please reach out to VedFirms.